0261 - 2557700 / 2555566 / 9374574514

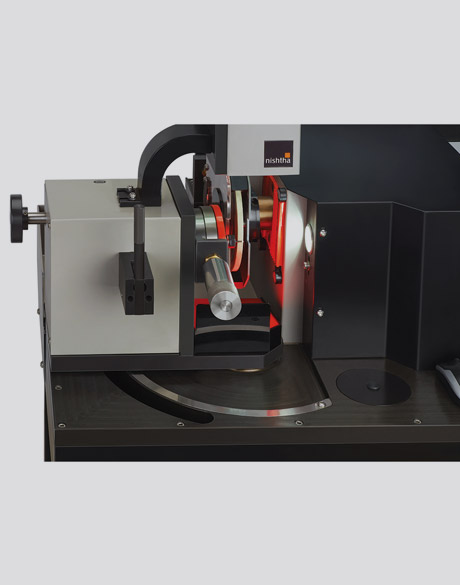

ALL IN ONE 3

For the first time in the world Nishta is presenting revolutionary diamond processing

AIM (Artificial Intelligence Machine) Technology.

Where diamonds are processed with minimum damage to the raw material. Key processes like coning bruting wit table can be done in this machine. Multiple tension selection available where the Tension-1,2,3 are used for normal diamonds.

Technical Specifications

- Dimension L 365 mm H 650 mm D 585 mm

- Weight 150 kg

- Voltage 230 V-50/60 Hz

- Power Sonsumption 0.60 Amp

- Operating System Windows 7 or higher.

- Z-Axis Not Available

- Diamond Size Up to 1.5 Crt

- Wheel Motor BLDC with Belt Drive

- Sensor Accuracy 5 sensors feed back system

Features

Table Single Facet rest of the processes can be performed on this machine but increase in risk during faceting operation.

Facets can be made with perfect symmetry at the bottom and top.

Facets can be made by selecting the inclusion as per galaxy.

Automatic Feed Pressure is decided by the machine itself. No need for any manual settings for pressure increase & decrease

As the pressure is maintained automatically through the software, even risky diamonds can be processed with ease.

2 to 4 machines can be operated by a single operator.

Automatic movement of the degree gives highest accuracy to the coning process.

As the angle moves automatically, the diamond can be processed at the nearest degree of sarin. Therefore, it can be polished more speedily and accurately.

As the diamond moves at minimum places, its management too is minimized along with it.

Multilingual (Gujarati, Hindi and English) user-friendly software.

The ceramic wheel cutting in presence of water keeps the stone cool during the cutting process.

Automatic water On/Off during the brutting process (Water tank and water pump included).

Automatic lubrication of all the mechanical parts determined by the software and performed at regular intervals for a longer life of the machine (Lubrication Pump included).

Advanced multiple micro controllers are used to control all the processes.

Rigid and reliable mechanism. Less prone to wear and tear for a long time, hence less services.

Each operator can set his password and can change setting as per permission given to him by the manager.

Video recorded of the processing of each diamond keeps the complete log of the processed stones.